Each entrepreneur who decides to expand their business from a one-man company up will soon feel the need for a system which would coordinate the work of their employees. Where and how they should begin - that is exactly what this article deals with.

Preparation of the system is pretty simple for all those who have ever worked in a system and, better still, been at its birth. A quality advisor should be able to master this procedure with bravura. At this point, we are introducing to you one of a number of procedures that is designed to take you directly to the finish line, fast and without making needless detours.

1. Requirements of the system - choose which requirements are essential for your system. They will be the requirements of the quality assurance system according to ISO 9001, or the environment protection system according to ISO 14001, or safety of work system according to OHSAS 18001, or safety of information system according to ISO 27000 or it will be a multiple-requirement system, an integrated system.

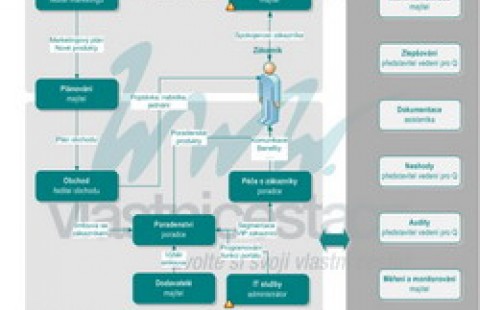

2. A modelling and descriptive method - select which outputs and system description would suit your company best and be convenient for your workers. A modelling method has a strong effect on the following changes in the system. As a suitable tool here, you might use Microsoft VISIO, for instance. At this stage, it is also appropriate to determine the system´s structure.

3. Information system support - the resulting system is heavily dependent on whether or not you have introduced some information system in which you keep your orders, inventory and so on. Description of the system´s functioning will then refer to the information system you use and everything goes markedly simpler. However, companies mostly have no information systems and the prepared system description will later become an assignment for someone who implements the information system.

4. Deadline date for the system implementation - set the date when you need to have the system ready beforehand. Subsequently direct all your activities towards this date, for without the final deadline no system is easy to complete. The best way will be to make the responsible persons interested in meeting such a deadline.

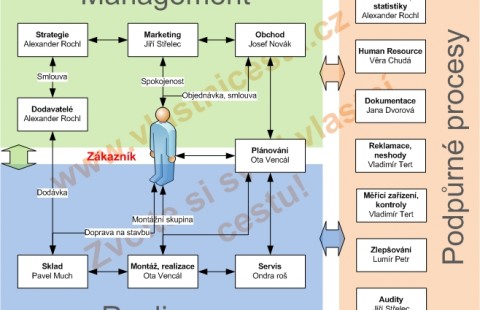

5. Process map - in the first place, define the principal processes and the sub-processes that you need to manufacture your products or to ensure the services you provide.

6. Preparation flow-sheet - measure time needed for launching the system preparation from the set deadline date bacwards. Fill into the flow-sheet each process, sub-process, approval, record making, database, check, audit, training, reporting that has been defined and, also, the time reserved for inspecting the cohesion among the individual processes. Do not forget you need to have instructed and trained internal auditors if you want to have the ISO certificate. Auditors can be hired externally, which is appropriate in the initial stage.

The Real | Interim Manager for Your Changes

Manager work model

Time management - making use of time effectively

Jak správně tvořit mapu procesů

Modelling and setting the processes and procedures - ISO 9001

Training - preparation of the SWOT analysis and strategy

Company Management System of Quality Step by Step - ISO 9001

Process map acc ISO 9001 - business offer

IT staff communication

7. Setting the processes - define a clear-cut form in which each process is going to be described, whether you will use flowcharts or only texts etc. At this stage, working with the person responsible or the process owner, describe each process already described in the process map. In simple processes count circa 2-3 hours per process. Processing time grows with the complexity up to 15-30 hours.

8. Training in processes and the system - train workers for those processes they are going to work with. The best routine is to train workers continuously as the particular processes are being prepared. Eventually, it is helpful to train the system as a whole showing everybody the way the individual processes are interlinked and how the company is going to benefit.

9. Test run - following the system preparation let the system running. Watch it at work and see how the workers respect the set rules, whether there are any incompliances and, if so, how these are resolved.

10. Internal audits - subsequently get internal audits started and verify each process and how it functions. After the audits have been finished, make all incompliances, errors, found good.

11. Evaluation of functioning - evaluate all that works and how it works. Utilize the process metrics and the set-up reporting. Prepare the system for review by the management.

12. Certification audit - if the system works, have an independent certification auditor (it is advisable to choose a certification company early in the process) check your company. These are the most essential steps in the preparation and implementation of the comapny´s management system. Each of them would deserve to be dealt with separately in an article, yet it is sometimes better to call for an advisor who will lead you through every step of the preparation.

Time for the system preparation

You would surely like to know how long the quality system preparation will last. In my experience, the preparation time ranges as indicated in the tabel below. The times may vary up and down depending on the workers´ interest and devotion. Sadly, entrepreneurs save most time in trainings, test runs and audits. That subsequently has negative ramifications in the system´s future functioning.

*Note.:Well, in fact, in the Czech Republic it is not such a big deal frankly, because a certification company will always issue the cerficate, if you pay them. There are really few certification companies that would refuse to comply, if they found an insufficiently prepared system.*

| Stages/company size acc. to workforce | 5-10 | 10-20 | 20-50 | 50-200 |

|---|---|---|---|---|

| 1. Requirement for the system | 1 days | 1 days | 1,5 days | 2 days |

| 2. Modelling and descriptive method | ||||

| 3. Information system support | ||||

| 4. System implementation deadline | ||||

| 5. Process map | ||||

| 6. Preparation flow-sheet | ||||

| 7. Process set-up | 5 days | 6 days | 10 days | 20 days |

| 8. Training in processes and the system | 1 day | 2 days | 3 days | 5 days |

| 9. Test run | 30 days | 45 days | 60 days | 75 days |

| 10. Internal audits | 2 days | 3 days | 5 days | 10 days |

| 11. Evaluation of functioning | 1 day | 1 days | 2 days | 3 days |

| 12. Certification audit | 1,5 days | 3 days | 4 days | 9 days |

| Total | 41,5 days | 61 days | 86,5 days | 124 days |

The preparation period is strongly determined by the following factors:

- Industrial branch and specialization

- The scope of the system that an entrepreneur has decided to create

- Integration of systems – quality (ISO 9001), environment protection (ISO 140001), safety (OHSAS 18001), IT services (ISO 20000)

- Interest of an entrepreneur in having a functional system of quality

- Financial and time resources

If an entrepreneur owning a company of 5-10 people takes the decision to prepare the system fast and locks himself away with an experienced advisor for three days out of the reach of the company day-to-day operation, they are able to prepare almost the whole system. The implementation procedure has been elaborated based on the experience of many years.