An increase in working with the so-called soft data has demaned new approaches and methods of processing. Today, hardly any company can do without them. This is exactly the reason why we have the 7 new tools of quality.

Why have the tools of quality come into existence?

Lately we have seen the character of companies and their needs transformed significantly. Production is no longer solely about iron processing or turning out electronic components. Software design, information processing, working with ideas have been taking ever bigger chunk of the total production. Simply put, the soft data is taking the center stage and it needs to be combined with the hard data (measurable). In order to achieve this we are supposed to utilize new methods in the sphere of the quality improvement. Such a need is fulfilled by the 7 new tools of quality.

In brief, the reasons for the 7 tools might be summarized as follows:

- to express thoughts, ideas, views

- to find links and relationships of importance

- to detect similarities and affinities

- to express causal relationships

- to visualize detected relationships

- to work in a team of experts

Nowadays, proving the quality is there is not enough. A continuous quality improvement appears to be the norm. Finding new possibilities for the company to develop and for their products to be improved is essential.

Here are the fundamental tools to improve the company´s quality:

| Tool / method of quality | Purpose, function of method |

|---|---|

| 1. Affinity chart | to get orientated in the huge volume of data |

| 2. Relationship chart | to grasp the relationships among the data and identify the important ones |

| 3. Tree chart | to simplify a great problem into elements that are easier to resolve |

| 4. Matrix chart | to better the arrangement of data and its relationships for further processing |

| 5. Matrix analysis chart | to detect relationships in well-arranged data |

| 6. Network chart | resource planning in time, looking for an optimal way |

| 7. PDPC chart | to identify the critical spots as early as the planning stage and find countermeasures |

Application of the 7 new tools of quality

The tools can be used independently or all at once. It depends on the type of company and the particular problem that is being resolved. Anyway, detecting the causal relationships makes the core of every problem-solving. Even the detectives do just this. It is the charts which can put them on the right track, helping them uncover the many relationships among the subjects.

The Real | Interim Manager for Your Changes

Manager work model

Time management - making use of time effectively

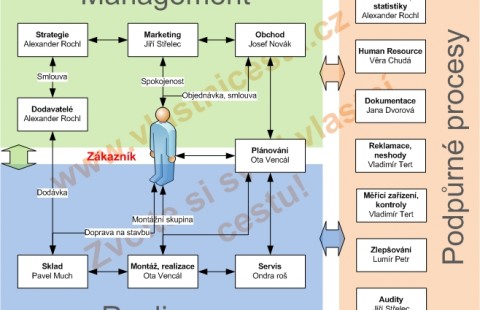

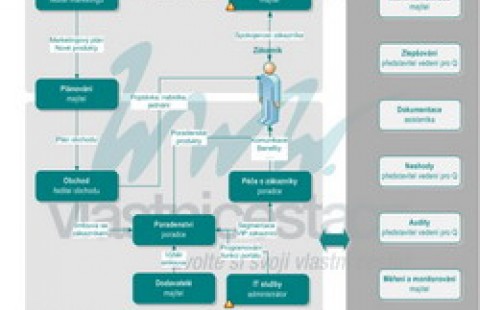

Jak správně tvořit mapu procesů

Modelling and setting the processes and procedures - ISO 9001

Training - preparation of the SWOT analysis and strategy

Company Management System of Quality Step by Step - ISO 9001

Process map acc ISO 9001 - business offer

IT staff communication

Today, these tools can also find their uses in the following spheres:

- software companies

- new product development

- marketing and Public relations

- and so on ...

Using these tools is not altogether trivial. It requires a thorough preparation and the knowledge how to apply the method correctly. I heartily recommend trying smaller-scale, simpler cases before you begin working on the problem itself. Practical problems tend to be markedly more complex and making mistakes always comes at a price. They are simply more expensive.

The 7 new tools of quality are focused on working with the so-called soft data. If you need to work with the hard data, use 7 tools of quality.

Require your consultant to practise a quality approach based on proven methods!

Should you need training/seminar for a particular method, feel free to contact our advisors.